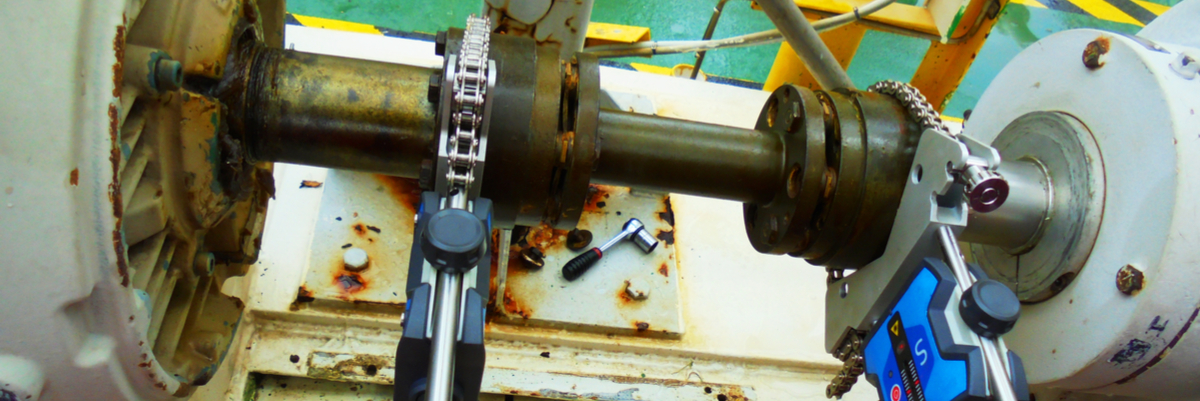

Laser Shaft Alignment

Laser alignment is the process to make two or more rotating shafts co-linear, or in the same straight line, both vertically and horizontally

Laser shaft alignment can be done utilizing several methods and tools, such as straightedges, callipers, dial indicators, optics, or laser systems. Of these, laser shaft alignment is the fastest and most accurate.

Make An EnquiryWhy Optimech?

Laser shaft alignment should be applied on all rotating equipment to eliminate problems such as:

- Overloads and vibrations

- Bearing wear and failure – due to excessive torque

- Wear and failure of seals

- Excessive power consumption – which can increase by as much as 20% on misaligned units

- Metal fatigue on shafts and journals due to misalignment

- Even in instances where flexible couplings are used it is a proven fact that the same stresses occur in bearings and shafts

Typical applications for shaft alignment

- Normal shaft – shaft/coupled units

- Gear box/pump – motor

- Drive trains

- Drive shafts/line shafts

- Offset drives/cardan shaft coupled offsets

Optimech Benefits

By correctly and accurately laser aligning shaft/ couplings etc., you will remove all the above problems normally associated with poor misalignment which is why our systems prove both cost effective and maintenance friendly.

Our Industry Sectors

Due to the nature of the process, machine alignment is crucial to a number of industries. Optimech apply our expertise to a number of different industries, all with specific requirements for alignment.